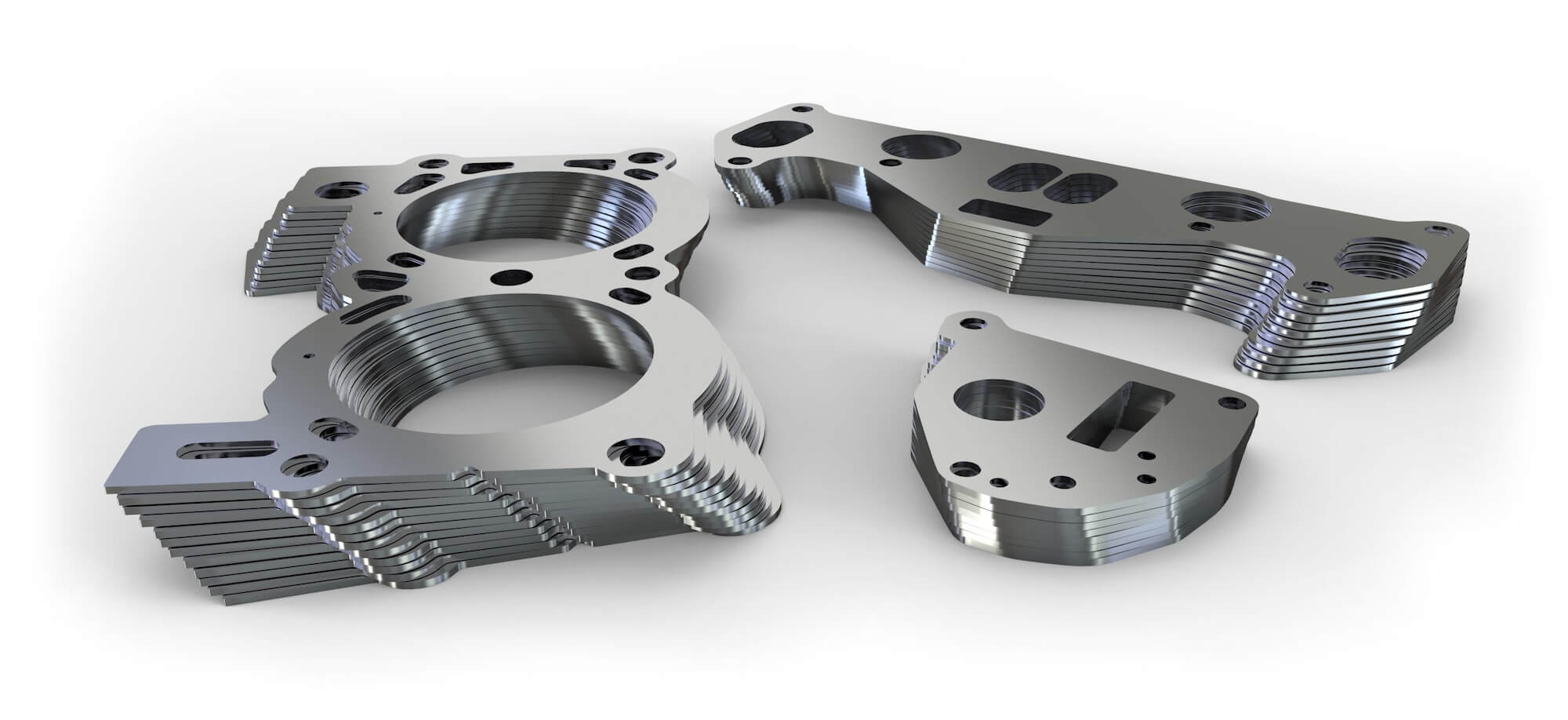

A Return To World-Class Manufacturing

A fourth generation, $20MM Precision Machined Products Manufacturer serving automotive, heavy truck and marine OEM and Tier 1 customers faced a challenging shift in its sales profile. In addition to a 15% sales reduction, orders shifted from a high volume, low mix to a low volume, high mix scenario. This transition was accompanied by variances surpassing the standard cost by 25%, leading to stagnant or declining trends across vital performance metrics.

Situation

The company grappled with elevated defect rates, scrap, and rework processes that culminated in an unacceptable Parts Per Million (PPM) rate, compromised customer quality, and a Cost of Quality (COQ) amounting to $1.2 million. Additionally, the facility’s outdated assets were proving unreliable and costly to maintain, with maintenance efforts consuming 89% of the allocated time and budget on mechanical failures. With an addressable cost base of $11 million, the company was projected to incur a loss of $1.5 million.

22%

Variance

Resulted from Non-Value Add (NVA) activities.

32%

Reduced Cost Base

Over 24 months.

$3.5MM

Savings

Annually.

Solution

- Board of Directors hired Lean Resources to conduct a plantwide benchmark study to validate the company’s standard cost model, identify performance gaps, and develop an improvement roadmap.

- Completed 2-week benchmark study to assess current state operational performance, identify key cost drivers and determine “Achievable Standards”.

- Prepared high-level analysis of projected financials, based on historical performance and projected efficiencies to support >5x return on investment.

- Developed Improvement Roadmap with high-value projects, key assumptions, financial impact, and timing.

- Established ONE-YEAR and THREE-YEAR targets that, when achieved, will clearly position the company as a model manufacturer with “World Class” manufacturing systems and practices.

Results

- Standard Cost Model was sound with 2% variance in Quoted Standard versus Operating Standard

- 22% variance resulted from Non-Value Add (NVA) activities across Direct and In-Direct categories, as “charged labor” and “paid labor” differed.

- Improvement Roadmap reduced the addressable cost base by 32% over 24 months.

- $3.5MM savings annually