Business

Transformation

Initiative

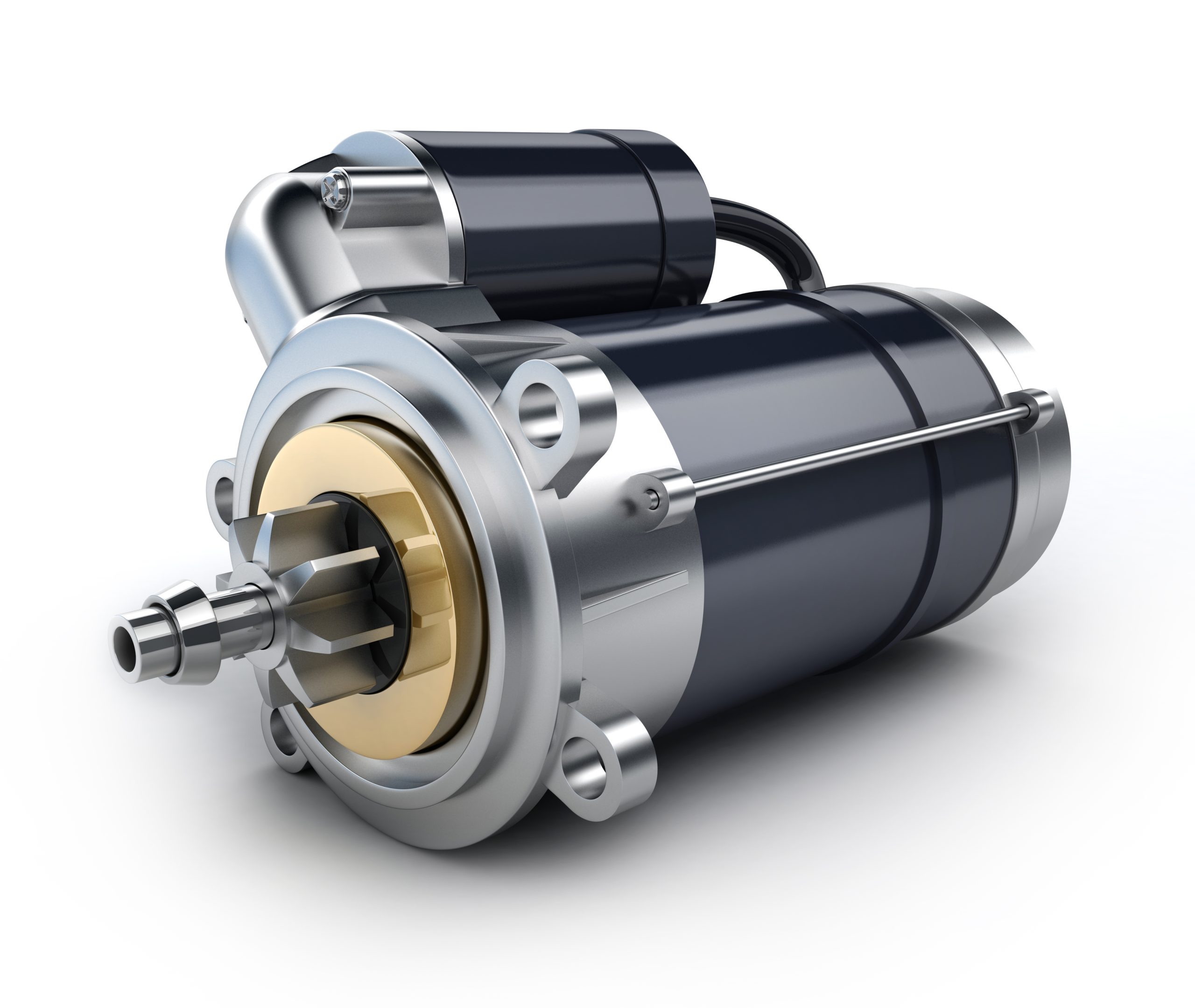

A manufacturer of components and assemblies for motors, generators, and transformers had experienced a steady decline in revenues and profit since 2008, reducing operation locations from 5 to 1 larger facility in the Midwest as losses exceeded $16MM. Despite an infusion of $13MM by new owners, the company’s performance remained stagnant as key leaders and management resources worked to balance operational priorities, ramp up integration activities, and adopt new operating requirements while maintaining high customer service.

Opportunity

Lean Resources launched a Site Transformation Initiative to improve performance, allowing the site team to focus on running the business while integrating Site Transformation activities. Lean Resources served as the manufacturing advisor, operations lead, and project manager for the business transformation initiative, supplementing the management team with additional leadership, project management, and implementation skills. Together the teams worked to substantially reduce costs, minimize cash burn, and improve the business while preserving core competencies and limiting daily distractions.

150-day

Recovery Plan

With annual performance benchmarks by the Project Manager.

$30MM

In Sales

Development of a revenue growth strategy targeting $30MM in sales.

12%

EBITDA

In three years.

Results

During the recovery plan, necessary measures were taken to reduce costs and cash burn, boosting company performance, delivering sustainable results, and addressing issues that were negatively affecting revenue and cost models. Financially, the company was able to generate a net operating profit in the fourth month of the recovery plan and exceeded the 2020 and 2021 revenue and EBITA targets. This success enabled the shareholders to exit, recoup their investment, and earn a slight return.

Notable Project Attributes

- Demonstrates expertise in cost reduction and financial performance enhancement.

- Two-week operational assessment by Lean Resources identified untapped company potential.

- Projected return on shareholders’ equity investments within 3-5 years.

- Creation of a 150-day recovery plan with annual performance benchmarks by the Project Manager.

- Collaboration with the local team to overhaul manufacturing processes.

- Implementation of capable, repeatable processes and alignment of personnel and skills.

- Formation of a high-performing team, strategic removal of select managers, and recruitment of top-tier leaders.

- Development of a revenue growth strategy targeting $30MM in sales and 12% EBITDA in three years.